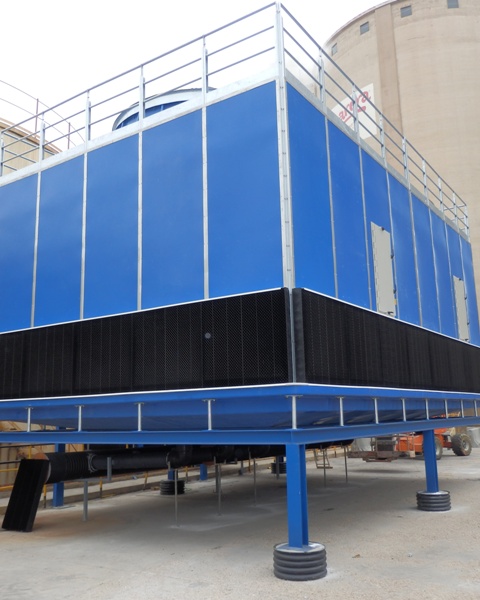

EWB

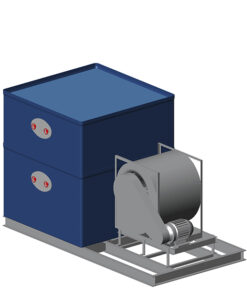

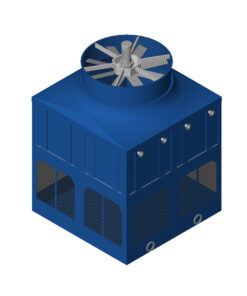

Open circuit Cooling Tower for big volumes and assembled on site

- Broad Range: From 500 to 10.000 m3/h

- Modular design, with hot galvanized profiled steel and FRP cladding

- Corrosion free

- Industrial applications

- Easy maintenance

- Laminar and dripping fillings

- German engineering

- Materials highly resistant to all aggressive conditions, as well as to extreme temperatures

- Low energy consumption

ASSEMBLY AND OPERATION – Download

PRODUCT CATALOGUE – Download

NOZZLE PRESSURE DROP – Download

SOUND LEVELS – Download

Reviews

There are no reviews yet.